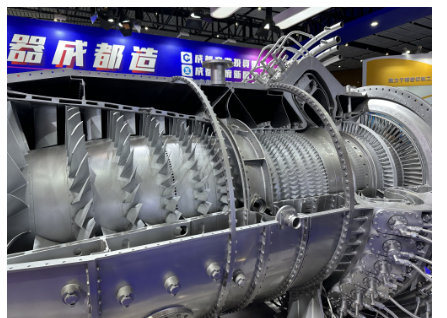

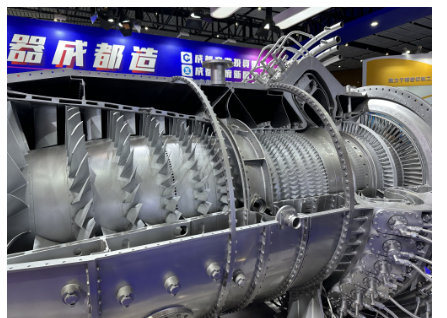

Luoyang Jinlu Carbide Tools Co., Ltd. participated in the GTF2024 Chengdu "two machines" exhibition to talk about the emerging trend and cutting-edge technology of "two machines"!

Thermal spraying technology is a new technology for strengthening and protecting the surface of materials, and it is one of the most effective techniques for surface modification in the field of surface engineering. Thermal spraying refers to the method of heating the spray material inside or outside the spray gun to a plastic or softened state, and then spraying it on the surface of the pretreated substrate, basically keeping the state of non-melting to form a coating. Using different heat sources and spraying equipment, a series of coatings with various functions such as anticorrosion, wear resistance, wear reduction, high temperature resistance, oxidation resistance, heat insulation, insulation, conductivity and microwave radiation protection can be prepared.

Thermal spraying technology can repair the old and waste in equipment maintenance, so that the scrapped parts "back to life"; It can also be strengthened and pre-protected in the manufacture of new products to "prolong life". It plays a large role in saving energy, saving materials, improving efficacy and reducing costs, especially suitable for China's national conditions, in line with our current economic policies, and is an important practical technology currently advocated by the state for energy conservation and emission reduction, low energy consumption and high efficiency.

1. Application status of thermal spraying technology

Thermal spraying technology, as a new modern processing technology involving a wide range of technologies, relatively simple and flexible processing technology, wide application range, and large economic benefits, the coating surface has wear-resistant, anti-corrosion, heat insulation, conductive, insulating, anti-erosion, anti-oxidation, anti-friction, lubrication, anti-radiation and other functions. It can be used not only for the repair and surface strengthening of mechanical parts, but also for manufacturing.

Due to the wide selection of spraying materials, not limited by the overall material alloying, it is more convenient to obtain superhard alloys, various ceramic or cermet coatings and various functional coatings, and the coating relative to the overall advanced materials, the amount of material is less than the overall improvement of the material is undoubtedly much more economical, so valuable materials can be used, and its cost will not increase much. The surface performance of the material can be greatly improved, and the service life of the parts repaired by thermal spraying can generally reach or even several times more than the new products.

Coating materials cover almost all solid engineering materials, including metals, alloys, ceramics, cermet, plastics, metal-plastics and their composites, and other inorganic nonmetallic materials. At present, it is widely used in aerospace and industrial gas turbines, boilers, petrochemical industry, printing, paper, general machinery, rotating target and functional coating and steel industry, and thermal spraying materials have played a great role in promoting the long-term development of these industries.

2. Future development trend and prospect of thermal spraying technology

From the perspective of the future development trend, the research of thermal spraying system engineering will be paid more attention. At present, many countries have strengthened the research of thermal spraying system engineering, starting from failure analysis, through the optimization of surface pretreatment, spraying equipment, spraying materials and spraying process, the thermal spraying implementation process plan has been developed. In the process of development, thermal spraying technology and other disciplines cross permeate each other to form a new surface treatment process. In the future, thermal spraying technology may carry out effective research and development in the selection of spraying materials, the bonding strength of coating and substrate, the research of basic theories, the research and development of new spraying materials, the research and development of spraying processes and equipment, and the expansion of new application fields.

3. Luoyang Golden Egret hard surface material product series introduction

Luoyang Jinlu Carbide Tools Co., LTD. Hard surface materials products mainly include agglomeration sintering thermal spraying powder, sintering crushing thermal spraying powder, plasma surfacing powder,

Laser Cladding Powder, self-fusing alloy powder, sprayed

Tungsten Powder, sprayed molybdenum powder, cemented carbide particles,

Cemented Carbide Pellets, tubular electrode, flexible

Welding Rope, nickel-based

Welding Rod, etc. Products have been widely used in iron and steel industry, textile printing and dyeing industry, printing and paper industry, petrochemical industry, automobile and shipbuilding industry, machinery manufacturing industry, etc.