Ms. Fiona Cui

Leave a message

Ms. Fiona Cui

Leave a messageLuoyang Golden Egret Geotools material product series-Introduction to the application of Thermal Spray Powder to wear resistance strengthening of tooth surface of corrugated roller in paper making.

Thermal spraying technology is a mature surface strengthening and protection technology, and is an important part of surface modification. With the development of science and technology, thermal spraying technology has achieved good results in the wear resistance of the teeth of paper making corrugated rod and has been widely promoted and applied. Corrugated roller as the core part of the cardboard line, in its use process is a continuous wear process, its wear resistance and service life are the main technical indicators to measure its quality and economy. Due to the shape of the corrugated roller, the surface of these parts need to be repaired at a high cost, through thermal spraying technology to repair the corrugated roller, has a good economy, so that the service life of the corrugated roller is greatly extended, reaching 3-6 times of the chrome layer.

The thermal spraying powders used by Luoyang Jinlu for paper making corrugated rollers are mainly WC-12Co and WC-10Co-4Cr series, with uniform composition, concentrated particle size distribution, stable bulk ratio and high sphericity. Using thermal spraying process to form a WC-based coating structure on the surface of the corrugated roller, the coating with high hardness, high wear resistance, low porosity and low surface roughness can be prepared, which greatly improves the working life of the corrugated roller, reduces the surface treatment cost and has excellent economy.

01Product Series

| Product series | Grade | Specification | Powder type | Apparent density |

|

WC-12Co | GP12-2 | -38/+15 | Agglomerated and Sintered | 4.3-5.0 |

| GP12U-19 | -30/+5 | Agglomerated and Sintered | 4.7-5.6 | |

| WC-10Cr-4Cr | GP10CU-19 | -30/+5 | Agglomerated and Sintered | 5.0-6.2 |

02Coating property

The coating performance obtained by high velocity oxygen fuel process is excellent, as follows:

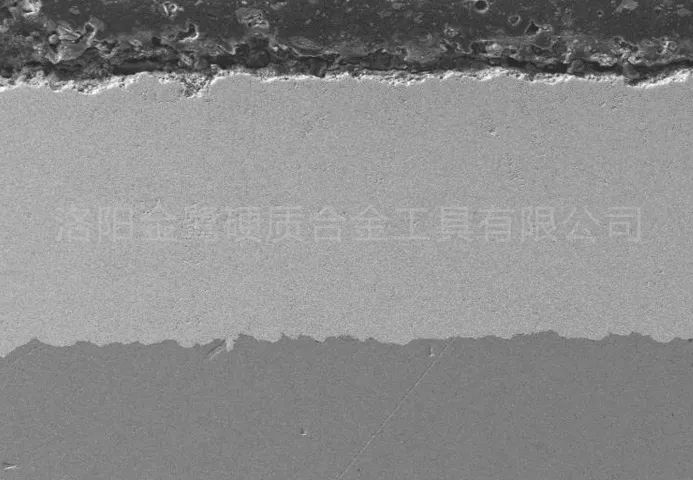

001 Metallographic structure

The coating is compact, well combined with the matrix interface,

no oxide inclusion, and WC hard particles are evenly distributed.

002 Porosity

Porosity<0.3%

003 Bond strength

The coating bonding strength is greater than 70MPa

004 Microhardness

The indentation of coating microhardness test is in good condition, without collapse, and the hardness is uniform

WC-12Co HV0.3 1100-1200;

WC-10Co-4Cr HV0.3 1100-1250;

005 Corrosion resistance of coating

After the standard neutral salt spray test, no obvious corrosion traces appeared in the coating samples after 240H

Application of thermal spray powder for abrasion resistance strengthening of tooth surface of corrugated roller for paper making

| Product series | Grade | Application description |

|

WC-12Co |

GP12-2 | The medium particle WC is used to obtain excellent wear resistance and impact resistance ductile spraying materials. Mainly used in corrugated roller carton machinery, single-sided machine, suitable for A/B/C corrugated type; |

|

GP12U-19 | Using fine particle WC, the coating is more dense and the surface roughness of the coating is low; Recommended for E/F/ corrugated type, high coating hardness, good wear resistance. | |

|

WC-10Co-4Cr |

GP10CU-19 | Fine particle WC is used to obtain excellent wear resistant and corrosion-resistant coating structure, with dense coating and low surface roughness; Mainly used in A/B/C corrugated type, coating hardness is high, good wear resistance. |