Vacuum induction melting gas atomization (VIGA process)

Vacuum induction melting gas atomization method means that in vacuum environment, the coil induction heating principle is used to melt the charge, after reaching a certain temperature, the melting chamber and atomization chamber are filled with atomizing gas, and then the molten steel is poured into the tunic, and the metal liquid flow is formed through the nozzle into the atomization chamber [18], and then the high-pressure inert gas is used as the atomizing medium to break the continuous metal liquid flow. It quickly solidifies into fine particles, that is, metal powder. FIG. 1 shows the schematic diagram of aerosol vaporization principle.

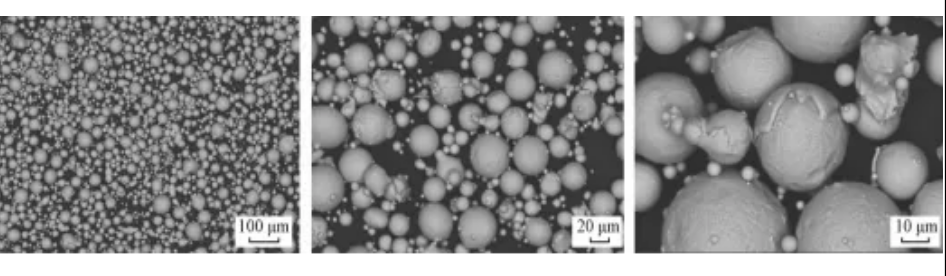

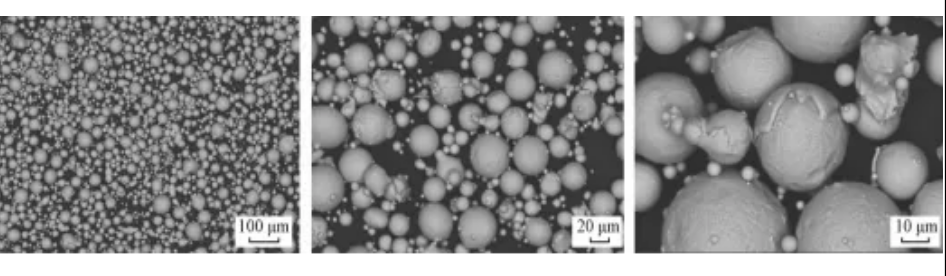

Figure 2 shows the powder produced by vacuum induction melting gas atomization process. From the surface morphology, it can be seen that the particle size of the powder obtained by gas atomization method is dispersed, generally about a few microns to more than 100 microns, and the sphericity is preferred, but there are satellite powder and adhesion powder.

Company product profile:

Luoyang Golden Egret Geotools Co.,Ltd. founded in2012,is wholly-owned by iisted company XiamenTungsten Co.,Ltd (XTC).As a backbone cemented carbideenterprise of XTC with registered capital of 1.05billionRMB and first investment of ibillion RMB,GEOTOOLSspecializes in producing and selling high quality tungstenpowder,

Tungsten Carbide Powder, carbide anvils,carbideroll rings,carbidesubstrates for PDC bit,mining drill bitsand hard facing materials.

Based on decades of production experience of WC based hard-facing materials, world-class technologies and modernautomatic production lines, GEOTOOLS dedicates into development and production of high quality hard facing materialwith high hardness, best wear resistance, best corrosion resistance and application solutions.

XTC brand

Thermal Spray Powder mainly includes Wc- based & Cr3C2-based. The WC coating has high hardnessdurable wear resistance, abrasion resistance, corrosion resistance and high bonding strength, mainly used in oil &gas valves, mining tools, injection screws and printing machinery parts, The Cr3c2 coating has higher thermalstability and anti-oxidation, which can be used in a high temperature and corrosive environment, e.g. inner- wall ogas pipeline and pump.

With high degree of sphericity & excellent alloy organization, cemented carbide pellet is mainly used in weldingas an additive material of

PTA Powder and tubular weldina rod to improve the wear resistance of the work pieces.